What Are Standing Seam Panels?

Standing seam panels are a popular choice for roofing systems due to their durability, sleek appearance, and weather-resistant qualities. These panels consist of long, interlocking metal sheets that form raised seams along the roof. The seams are designed to stand above the surface of the panel, providing both structural strength and a visually appealing finish. Standing seam panels are most commonly made from materials like steel, aluminum, copper, or zinc and are used in both commercial and residential roofing applications.

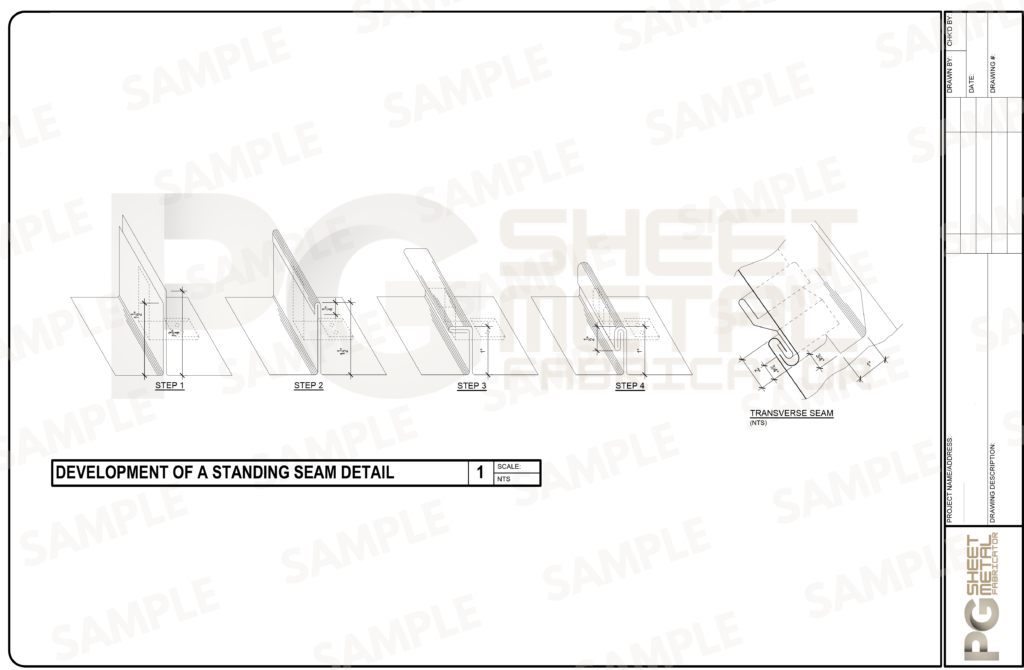

The key feature of standing seam roofing is the raised seam, which is created by mechanically folding the edges of adjacent panels. This ensures that there are no exposed fasteners, making the roof system more resistant to leaks and weather damage.

Benefits of Standing Seam Panels

- Weather Resistance: Standing seam panels are designed to withstand harsh weather conditions, including rain, snow, and high winds. The hidden fasteners and raised seams prevent water from entering the roof, ensuring superior waterproofing.

- Durability: Made from high-quality metals like steel and aluminum, standing seam panels are resistant to rust, corrosion, and fading, ensuring a long lifespan for your roof.

- Aesthetic Appeal: With their clean, modern look and smooth lines, standing seam panels add a contemporary touch to both residential and commercial buildings. They are available in a variety of colors and finishes to suit different architectural styles.

- Low Maintenance: Unlike traditional shingle or tile roofs, standing seam panels require minimal maintenance. The durable materials and design ensure that the roof will perform well for decades with little upkeep.

- Energy Efficiency: Standing seam roofs can help improve energy efficiency by reflecting sunlight and reducing heat absorption. This can lead to lower energy costs, especially in hot climates.

- Fire Resistance: Metal roofs, including standing seam systems, are highly fire-resistant, providing added safety to buildings.

Applications of Standing Seam Panels

- Residential Roofing: Standing seam panels are a great choice for homeowners looking for a modern, long-lasting roofing solution that requires minimal maintenance.

- Commercial Roofing: With their superior durability and weather resistance, standing seam panels are commonly used in commercial buildings such as offices, schools, and retail spaces.

- Industrial Roofing: In industrial settings, standing seam panels provide a strong, reliable roofing system that can withstand heavy loads, exposure to chemicals, and extreme weather conditions.

- Architectural Metalwork: Standing seam panels are used for various architectural applications, including cladding, accent walls, and facades, offering a sleek and stylish look.

Materials for Standing Seam Panels

- Aluminum: Lightweight, corrosion-resistant, and available in a range of finishes, aluminum is an ideal material for standing seam panels, especially in coastal or humid climates.

- Steel: Known for its strength and durability, steel standing seam panels are commonly used for both commercial and residential applications.

- Copper: Copper standing seam panels provide a unique aesthetic and develop a natural patina over time, adding character to the building’s appearance.

- Zinc: Zinc is a durable, eco-friendly material used for standing seam panels. It is resistant to corrosion and develops a protective patina as it ages.

How to Install Standing Seam Panels

- Prepare the Roof Deck: Ensure the roof deck is clean, dry, and level before starting the installation. A solid deck is crucial for a successful standing seam roof.

- Install the Underlayment: Lay down an underlayment, such as a breathable membrane, to provide additional protection against moisture.

- Position the Panels: Starting from one end of the roof, position the first row of standing seam panels. Ensure the panels are aligned properly and the seams are positioned correctly.

- Secure the Panels: Attach the panels to the roof deck using hidden fasteners or clips. These fasteners are designed to be concealed within the seams, ensuring a clean look and preventing exposure to the elements.

- Join the Panels: Interlock each panel into the next to create a continuous, watertight surface. Use the raised seams to connect the panels securely, ensuring that the roof is fully sealed.

- Trim and Seal: Trim the panels as needed for the roof edges and install trim pieces around the perimeter to finish the installation. Apply sealant to any joints or transitions to ensure a tight seal.

Why Choose PG Sheet Metal for Standing Seam Panels?

PG Sheet Metal specializes in crafting custom standing seam panels that offer a perfect blend of aesthetics, durability, and performance. Whether you’re building a new home, upgrading a commercial facility, or seeking a long-lasting roofing solution, our standing seam panels are designed to meet your exact needs.

We offer a range of materials, including aluminum, steel, copper, and zinc, and our panels can be customized to fit any roofing system. With expert craftsmanship and premium materials, PG Sheet Metal ensures that your standing seam roof will provide lasting protection and an attractive appearance.

Contact Us Today

If you’re looking for high-quality standing seam panels for your roofing project, PG Sheet Metal is here to help. Visit PG Sheet Metal or call 917-719-3513 to learn more about our custom metal solutions and request a quote.