What Are Miter Corners?

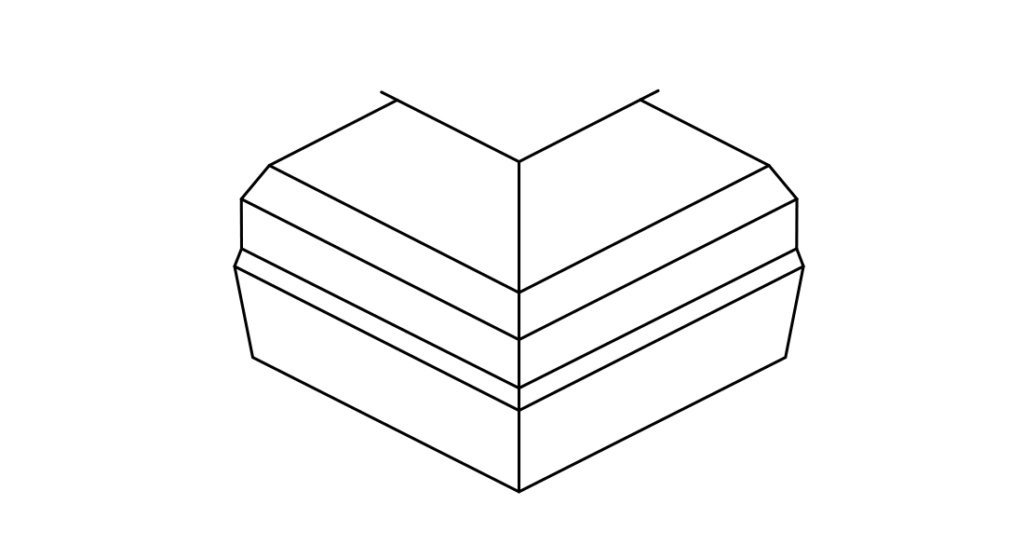

Miter corners are angled joints used to connect two pieces of metal at precise angles, often at 45 degrees, to create a clean, seamless corner. These are crucial in metal roofing, gutter systems, and cladding projects where sharp, clean angles are needed to maintain both the aesthetic and structural integrity of the installation. Miter corners ensure that the edges of your materials fit together perfectly, providing a strong, professional finish.

Benefits of Miter Corners

- Precise Angles: Mitered corners allow for sharp, clean angles that are essential for creating visually appealing, tight-fitting joints.

- Enhanced Durability: Mitered joints provide better strength and resistance, reducing the risk of gaps or leaks compared to other jointing methods.

- Seamless Aesthetics: Miter corners create a smooth, polished appearance with no visible seams, contributing to a high-end, professional finish.

- Versatility: Miter corners can be used in a wide range of applications, including roofing, gutters, downspouts, metal cladding, and custom fabrication.

- Weather Resistance: Properly installed mitered corners prevent water infiltration, improving the overall weather resistance of your roofing or cladding system.

Applications of Miter Corners

- Roofing Systems: Miter corners are essential for creating precise, water-tight connections at roof intersections and edges, particularly in custom metal roofing projects.

- Gutter Systems: Mitered joints are used to form smooth, tight corners in gutters, ensuring effective water flow and preventing leaks at junctions.

- Metal Cladding: For custom metal facades and wall cladding, miter corners help create seamless transitions between panels, adding to the modern, clean aesthetic of the building.

- Architectural Projects: Mitered joints are often used in custom metal fabrication projects, such as decorative elements, frames, or structural components, where precision and visual appeal are critical.

Materials for Miter Corners

- Aluminum: Lightweight, corrosion-resistant, and versatile, aluminum is a popular choice for miter corners in roofing, gutters, and cladding.

- Stainless Steel: Ideal for commercial and industrial projects, stainless steel offers excellent durability and resistance to corrosion, making it a reliable option for mitered corners.

- Copper: Known for its distinctive look and ability to develop a natural patina over time, copper is perfect for high-end, custom metal projects.

- Galvanized Steel: Offers durability and corrosion resistance, making it a great choice for gutter systems and roofing applications.

How to Install Miter Corners

- Accurate Measurement: Ensure precise measurements and angles are taken for both pieces of metal that will be joined. A 45-degree angle is typical, but this can vary depending on the design.

- Cutting: Use specialized tools such as a miter saw or shears to achieve clean, accurate cuts. The pieces should fit tightly together at the designated angle.

- Joining: Secure the pieces using metal fasteners, rivets, or welding, depending on the application and material being used. Ensure the joint is sealed properly to prevent leaks or gaps.

- Sealing: Apply a high-quality sealant or weatherproofing material to the joint to ensure that the mitered corner is water-tight and weather-resistant.

Why Choose PG Sheet Metal for Miter Corners?

PG Sheet Metal offers custom-fabricated miter corners designed to meet the precise needs of your roofing, gutter, or cladding project. Our experienced team uses high-quality materials such as aluminum, stainless steel, and copper to ensure that your miter corners are both durable and visually appealing.

With expert craftsmanship and attention to detail, we provide seamless, precision-fit miter corners that not only enhance the aesthetics of your project but also improve its functionality and longevity.

Contact Us Today

For durable, precise miter corners tailored to your specific needs, trust PG Sheet Metal. Contact us at 917-719-3513 or visit PG Sheet Metal to learn more about how our custom solutions can help bring your project to life.